SMS code login

Get SMS verification code

-

Home

-

About us

-

Product

Four row cylindrical roller bearing Double row cylindrical roller bearing Backing bearing Double row angular contact ball bearing Four point angular contact ball bearing Deep groove ball bearing Bi-directional thrust tapered roller bearing Double row tapered roller bearing Double row tapered roller bearing inch series Four row tapered roller bearing Four row tapered roller bearing inch series

Four row cylindrical roller bearing Double row cylindrical roller bearing Backing bearing Double row angular contact ball bearing Four point angular contact ball bearing Deep groove ball bearing Bi-directional thrust tapered roller bearing Double row tapered roller bearing Double row tapered roller bearing inch series Four row tapered roller bearing Four row tapered roller bearing inch series -

Stock Inquery

-

Solutions

-

Interchange

-

News

-

Contact Us

-

Imported rolling mill bearing replacement expert!Fully produced and processed according to SKF bearing standards,Reduce costs for enterprises, increase production capacity, save energy and increase efficiency.

Cracking of inner ring of hot-rolled high-speed be

2020-04-26

Failure bearing model:FC4666206

Failure location: inner circle

Failure mode: cracking along the axial position of the bearing inner ring

Failure phenomenon: The inner ring cracks after a certain period of time, and there is no regularity, and it appears at any position of the unit.

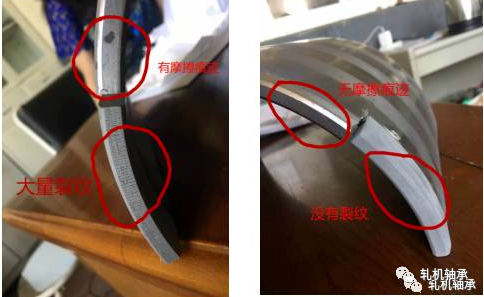

1.The technician cleans the bearing and inspects the bearing for damage. It is found that there are friction marks on one side of the bearing end surface, and none on the other side. Take the inner ring back to the factory for pickling inspection, and take the two end faces of the same inner ring respectively.

Observe the bearing end surface after pickling

Therefore, it is judged that the bearing cracking is caused by thermal cracking caused by end face friction. The only part that rubs against the end face of the bearing inner ring is the roller cone sleeve. Therefore, fix the cone sleeve and the roller to ensure that the cone sleeve does not run around the ring and prevent sliding friction with the inner ring.

2. After fixing the cone sleeve and testing for a period of time, it was found that the problem of cracking of the inner ring was not completely solved.

The technician measured the roll diameter on the spot and found that the roll diameter was too large.

Measure more than 10 new unused roll diameters;

Measure more than 5 new unused bearing inner rings.

The data obtained are:

Roll diameterø230+0.09;ø230+0.08;ø230+0.10;ø230+0.09; ø230+0.07 wait

Roller diameter sizeø230+0.07~0.10In the range.

Inner diameter of inner ringø230-0.00;ø230-0.01;ø230-0.00;ø230-0.01;ø230-0.00

The bearing inner diameter size conforms to the size range specified in GB / T308.1.

It can be seen from the above data that the interference between the bearing inner ring and the roll diameter is 0.07 ~ 0.11mm.

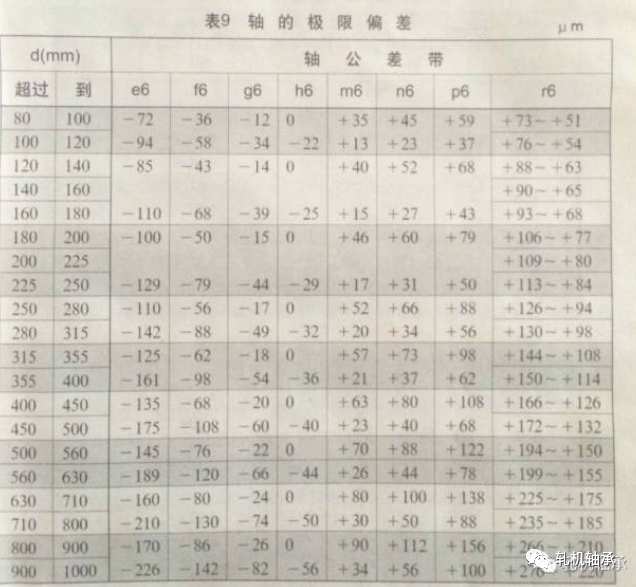

It can be seen from the table above that the inner diameter isøThe interference of the 230 bearing in the p6 tolerance zone is 0.05 ~ 0.079mm, and the r6 tolerance zone is 0.084 ~ 0.113.

The interference is within r6 tolerance zone.

This bearing is used in hot-rolling high-speed rolling mills, and the p6 tolerance should be selected. Therefore, the roll diameter of the roll is modified to ø230 + 0.05 ~ 0.07 in cooperation with the roll manufacturer.

After 3 months of usage tracking, the cracking of the bearing inner ring did not occur again.

Therefore, the reason for the cracking of the inner ring of the bearing is: the thermal crack caused by the friction of the end face plus the selection of the tolerance of the fit is not appropriate. Bearing failure should be found in many ways to solve the problem from the root cause.